Engine machining and balancing

COMPETITION & COLLECTION

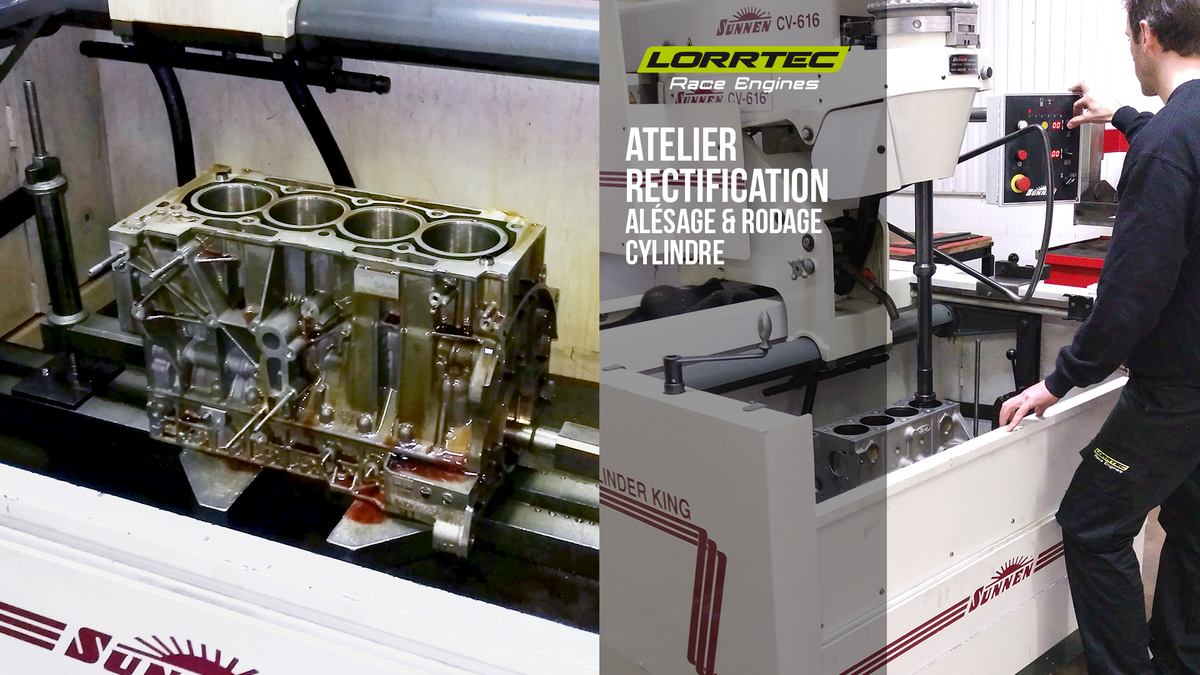

The LORRTEC engine machining and rectification workshop performs the following operations:

- Turning, conventional and CNC milling

- Engine block / cylinder head grinding

- Valve grinding

- Replacement and rectification of valve seats

- Replacement of valve guides

- Machining of CN cylinder head ducts

- Cylinder head and block test

- Cylinder bore (cast iron, alusil, nikasil…)

- Engine block liner

- Installation of DARTON reinforced liners

- Nikasil treatment

- Crankshaft grinding

- Crankshaft balancing

- Motorcycle crankshaft linkage

- Shaft line machining

- TIG welding

Presentation of LORRTEC’s machining, grinding and engine balancing activity.

The types of machining carried out by our workshop:

We carry out all the machining operations concerning car/motorcycle/aircraft engines… for competition and collection:

- rectification of valves and seats

- rectification Block / cylinder head

- cast iron cylinder bore, Nikasil, FRM…

- crankshaft grinding

- Crankshaft Balancing

- machining of CNC cylinder head ducts and combustion chamber

- 3D scan of the cylinder head ducts and combustion chamber

- welding aluminum cylinder head

- replacement of valve seats

- installation of bronze valve seats

- replacement of valve guides

- cylinder head/block test

- crankshaft line machining (Porsche 911…)

- single-cylinder motorcycle re-crankshaft

- etc…

Interview with Pierre-Antoine RAMPON on LORRTEC’s engine design office activity:

Does the machine shop work if the engine is not then assembled in-house?

Yes, we work both as a subcontractor for automotive professionals and for individuals who assemble their parts themselves.

What are the strengths of your machine shop?

We have a machine park that covers almost all of the machining operations , which allows us to control the quality and deadlines of our work. In addition, LORRTEC being primarily an engine manufacturer, we know the problems encountered during engine rebuilds, which allows us to guide our machining work and thus avoid any problem for the customer during reassembly.

What are your deadlines?

Depending on the operations, our lead times vary from a few days to a few weeks.

What are the specialties of your engine machine shop?

As an engine manufacturer, we are very attached to the absence of parasitic vibrations on our engines. For this, crankshaft balancing is essential, and that is why we have invested in a very precise latest generation Schenck balancer.

In addition, we have the equipment and the skills to carry out the engine bores on cylinders with Nikasil and others special treatments such as the FRM of the HONDA S2000 blocks … We measure the surface conditions (Ra, Rz, etc.) after machining in order to guarantee maximum sealing of the segments, and thus limit the consumption of engine oil.

We are also able to rebore the shaft lines, in particular on Porsche 911 engines with magnesium (and aluminum) blocks. In this case we rectify the 2 half-casings before machining centering pins and finally reboring the line. This process ensures perfect flatness, which is often lacking on these blocks, as well as precise alignment of the crankshaft bearings for greater reliability.

QUOTATION

How is a crankshaft balancing performed?

For a low engine balancing correct we must provide the whole of the “mobile hitch”, i.e. theset of rotating elements linked to the crankshaft (damper, flywheel, clutch, sprockets and pulley, screws, etc.). We first balance the crankshaft alone, then the flywheel and we finish with a check of the complete assembly. We are also able to balance the crankshafts of 3 and 5 cylinder engines, or even V engines which require the calculation and production of balancing weights (“bobweights”) according to the alternating and rotating masses linked to the crankpins (connecting rods and pistons).

All the activities of LORRTEC