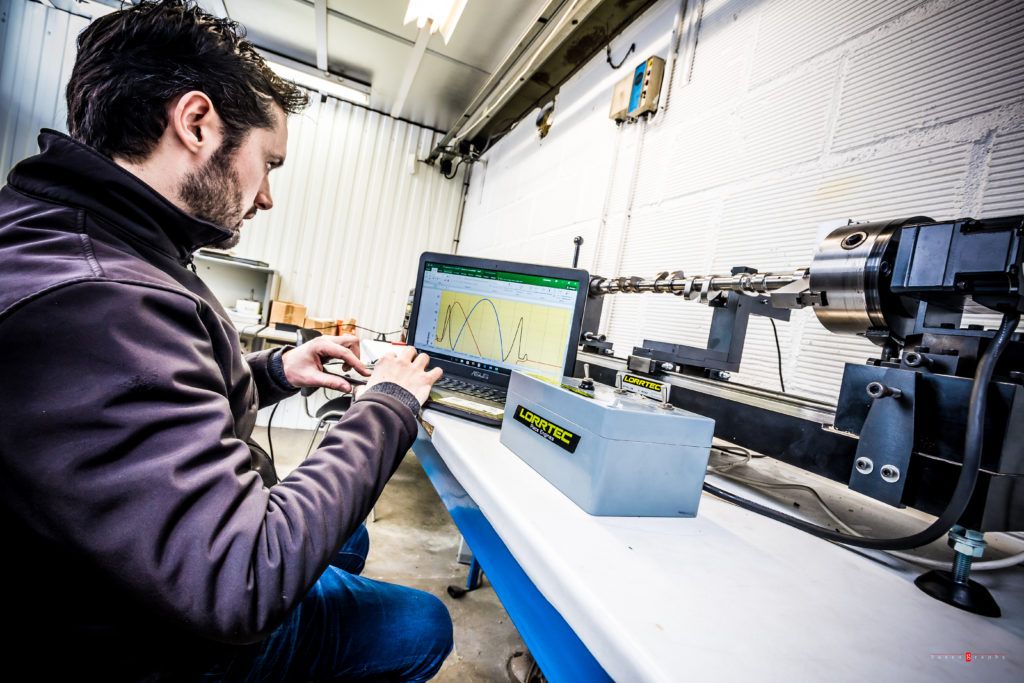

Engine design office

COMPETITION & COLLECTION

LORRTEC has a design office which applies its expertise in the design of all the components necessary for the development of a competition engine or a restoration of a collector’s engine.

Connecting rods, pistons, camshafts, crankshafts, valves… are designed or redesigned in the event of “reverse engineering”.

Presentation of LORRTEC’s high performance engine parts design office activity

Interview with Pierre-Antoine RAMPON on LORRTEC’s engine design office activity:

What is the point of an engine design office?

The design office enables us to design and develop internal engine components in order to increase either performance or reliability. It also allows us in some cases to recreate parts that no longer exist.

What types of parts do you design?

Our design office has the skills to define all the parts of an engine, the production then being carried out internally or externally according to the necessary means (machining, foundry, etc.). We frequently design pistons, connecting rods, valves, cups… We also calculate camshaft laws, springs… and we also design crankshafts, engine blocks and cylinder heads.

We have also developed CNC machining of cylinder head ducts and combustion chambers based on 3D scans.

Is the machining done in-house?

Yes most of the time, apart from moving parts (connecting rods, pistons, etc.) designed in our design office and then produced by world specialists (Mahle, Pankl, Carrillo, etc.). We now carry out 90% of our engine machining in-house.

QUOTATION

Series collection vehicles, VH and VHC

How do you deal with old engines for which there are no more parts?

Indeed, for historic vehicles the parts are often no longer available and/or no longer marketed by the manufacturers. When we have period pieces, we do “reverse engineering”: we study these pieces to understand the production process, and the reasons that led to it. The period pieces are the fruit of the knowledge that the engineers possessed, and of numerous experiments. Manufacturing techniques and materials have evolved, but we strive to recreate similar parts very close to the originals with increased reliability if possible.

Thus, on the Lancia 037 for example, we had to remanufacture the connecting rods, the pistons, as well as the intake manifolds in a foundry…

Another astonishing example: during the reconstruction of the PRV engines of the Peugeot 504 V6 that won the 2013 Morocco Rally, certain seals no longer existed, and we had to design and have specific seals made.

QUOTATION

Do you know how to determine the performance gain of the engine in the design office from a camshaft or piston drawing?

We are able to quantify values using simulation software and thanks to our experience. Then comes all the development work on the engine bench to validate the calculations made upstream.

What are the specialties of the LORRTEC design office?

There are many of them, we work on the calculation and optimization of camshaft laws, the design of reinforced and lightened connecting rod-piston assemblies, we draw and optimize the cylinder head ducts with the help of our wind tunnel and thanks to fluid mechanics software…

Who are the most famous LORRTEC customers?

To name just a few names: Vaison Sports, Mec Auto, Past Racing, Extrem plus, Two Wheel Drive, Rally Sport Classic, Equipe Europe, IMSA, Delage Sport…

QUOTATION

All the activities of LORRTEC